AI-based optimisation of demand planning

GROUP SCHUMACHER from Eichelhardt in Rhineland-Palatinate is a global player in the agricultural technology sector that develops, produces and sells components and wear parts for harvesting machinery. The company's diverse product range leads to long planning times for the procurement of raw materials. Another challenge is fluctuations in customer requirements, which result in high stock levels and overproduction. The AI pilot project aims to use AI to enable more efficient planning of demand and procurement.

Agricultural technology from Rhineland-Palatinate since 1968

GROUP SCHUMACHER is an internationally active, family-run agricultural engineering company. Since its foundation in 1968, the Group has specialised in the development and production of innovative components for harvesting machinery and wood maintenance. GROUP SCHUMACHER operates worldwide with over 600 employees in seven locations: Germany, the USA, Brazil, Russia and China.

Challenge: Fluctuating customer requirements and limited storage capacity

In a dynamic market environment, companies are faced with the challenge of coordinating supply and demand ever more precisely. Fluctuating customer requirements and limited storage capacities complicate planning and often lead to overproduction. Precise, forward-looking demand planning is important for demand-orientated production. Traditional planning processes usually react to changes with a delay and offer little flexibility to respond to short-term developments. The aim of this AI pilot project is to use intelligent and data-based forecasts to create greater planning reliability and thus sustainably improve production and procurement processes.

Precise demand forecasts through the use of AI

As part of the AI pilot project, an AI system is being developed that uses historical sales, purchasing and amortisation data as well as other globally related data to create precise forecasts of customer requirements.

The aim is to recognise patterns and correlations by intelligently analysing this data to derive well-founded planning for purchasing. Artificial intelligence serves as a central tool for data-based decision support and contributes to smarter management of procurement and production processes.

Sustainable business decisions through better planning and less overproduction

The targeted use of artificial intelligence in demand forecasting makes a significant contribution to increasing the company's operational value creation and resource efficiency. By precisely analysing the available historical data, the AI system can reliably predict future customer requirements. This enables raw materials to be procured in line with demand,reducing unused raw materials and overproduced items. This reduction has a direct positive impact on both the sustainability and profitability of the company, as storage costs and waste are reduced and production resources are utilised more efficiently. The developed AI model strengthens planning capability, reduces risks and promotes sustainable business decisions.

Sustainable business decisions through better planning and less overproduction

The targeted use of artificial intelligence in demand forecasting makes a significant contribution to increasing the company's operational value creation and resource efficiency. Through precise analysis of available historical data, the AI system developed can reliably predict future customer demand. This enables the procurement of raw materials in line with demand. As a result, unused raw materials and overproduced items are reduced. Over a period of one year, 153 tonnes of metals have already been saved, which corresponds to a material footprint of 1,042 tonnes and a carbon footprint of 280 tonnes of CO₂e. This reduction has a direct positive impact on both the sustainability and profitability of the company, as storage costs and waste are reduced and production resources are used more efficiently. The AI model developed improves predictability, reduces risks and promotes sustainable business decisions.

Technology

AI capability: Data analysis and prediction

AI models: AI-based assistant generates recommendations for demand planning

Value creation

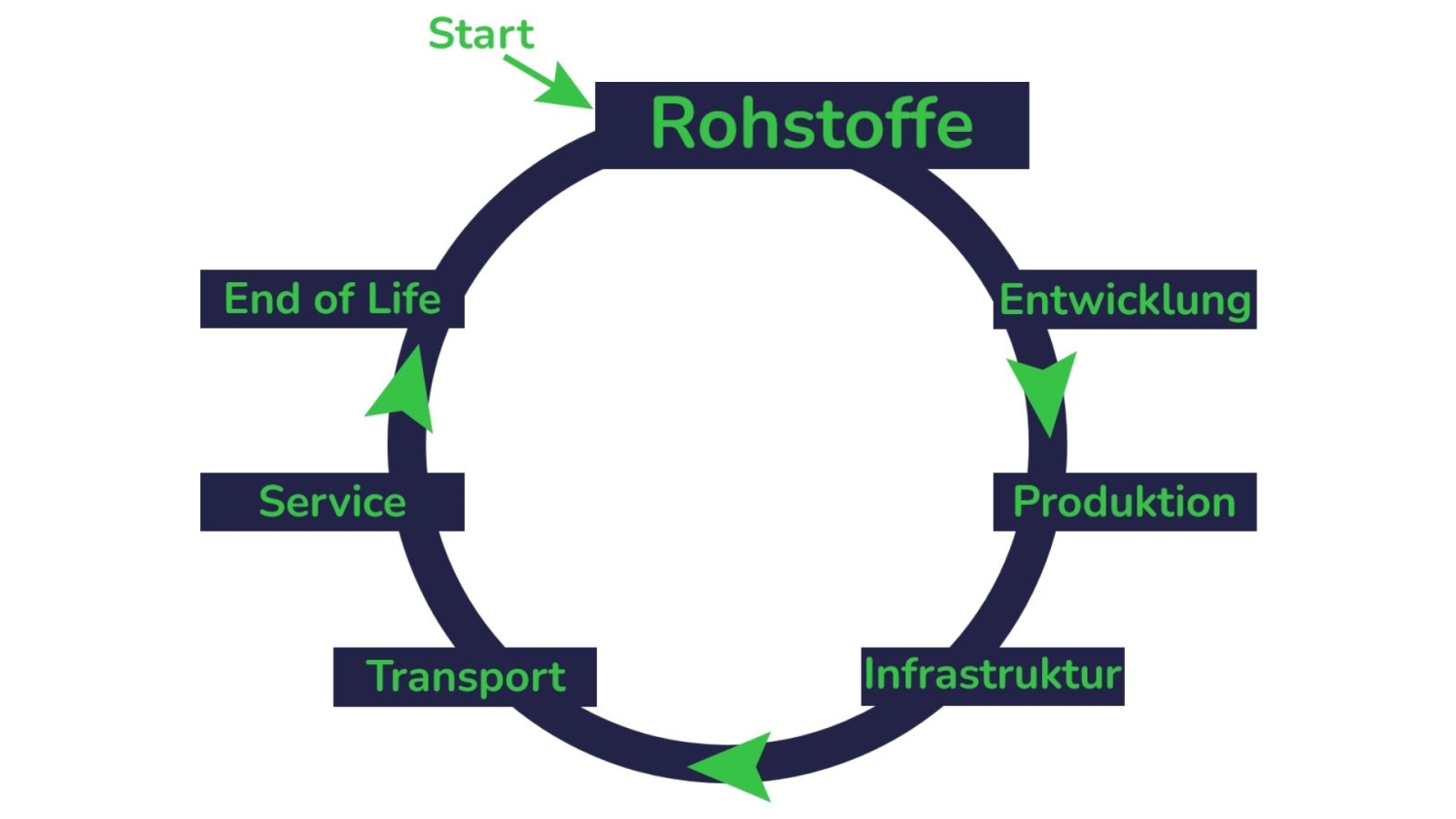

Phase: Purchasing planning & production

Aim of AI: Better demand planning

Resource efficiency

Data-supported demand planning leads to more precise planning, which reduces unused raw materials and overproduction.