Optimisation of the structural analysis for aluminium roofs using AI

Kalzip GmbH has been producing Kalzip roofs, an aluminium roof system that serves as the outer roof layer, for over 50 years. One of the biggest challenges for the company is to optimise the structural calculations to increase resource efficiency. The complexity of the calculations results from the large number of influencing factors such as the orientation, material thickness and geometry of the roofs. To overcome this challenge, an AI-based assistant is to be developed in the AI pilot project to support the company with the structural calculations.

Aluminium roof systems from Koblenz

Kalzip manufactures aluminium roof systems and determines the associated structural calculations. The so-called Kalzip, which is the outer roof skin, is manufactured from aluminium coils in a factory in Koblenz along with the accessories. The main component of all products is aluminium; individual components are only coated with plastic to prevent cold bridges . Static calculations, which are individualised for each roof, are also a central component of Kalzip's offer. The basis for this is the substructure, which can still be influenced depending on the project.

Challenge: More efficient use of resources during production

Kalzip faces the challenge of using resources more efficiently in structural calculations for aluminium roofs. Currently, thicker aluminium panels are often used to meet complex safety requirements, leading to increased material consumption. Currently, calculations are based on individual solutions and the experience of structural engineers, which does not always result in a more efficient use of resources. The automatic calculation of the ideal parameters by an AI-supported optimiser would achieve a better result. Furthermore, additional material can be saved by optimising the substructure.

Optimising the use of resources with the help of AI

The AI pilot project with the Green-AI Hub Mittelstand makes it possible to optimise structural calculations for aluminium roofs and reduce material consumption. An AI-based optimiser analyses existing design data and automatically suggests parameters such as the spacing of the beams and the material thickness. A prerequisite for the use of AI is the digitalisation and structuring of existing structural and project data. No new data needs to be recorded, as Kalzip already has an extensive inventory of relevant data. The new, AI-supported process largely automates the calculations and provides the structural engineers with proposed solutions, which then need to be checked and applied. The structural analyses consist of many parameters with complex dependencies. It is therefore impossible for a human being alone to check all variants and select the most resource-efficient one, however, together with AI, this is possible.

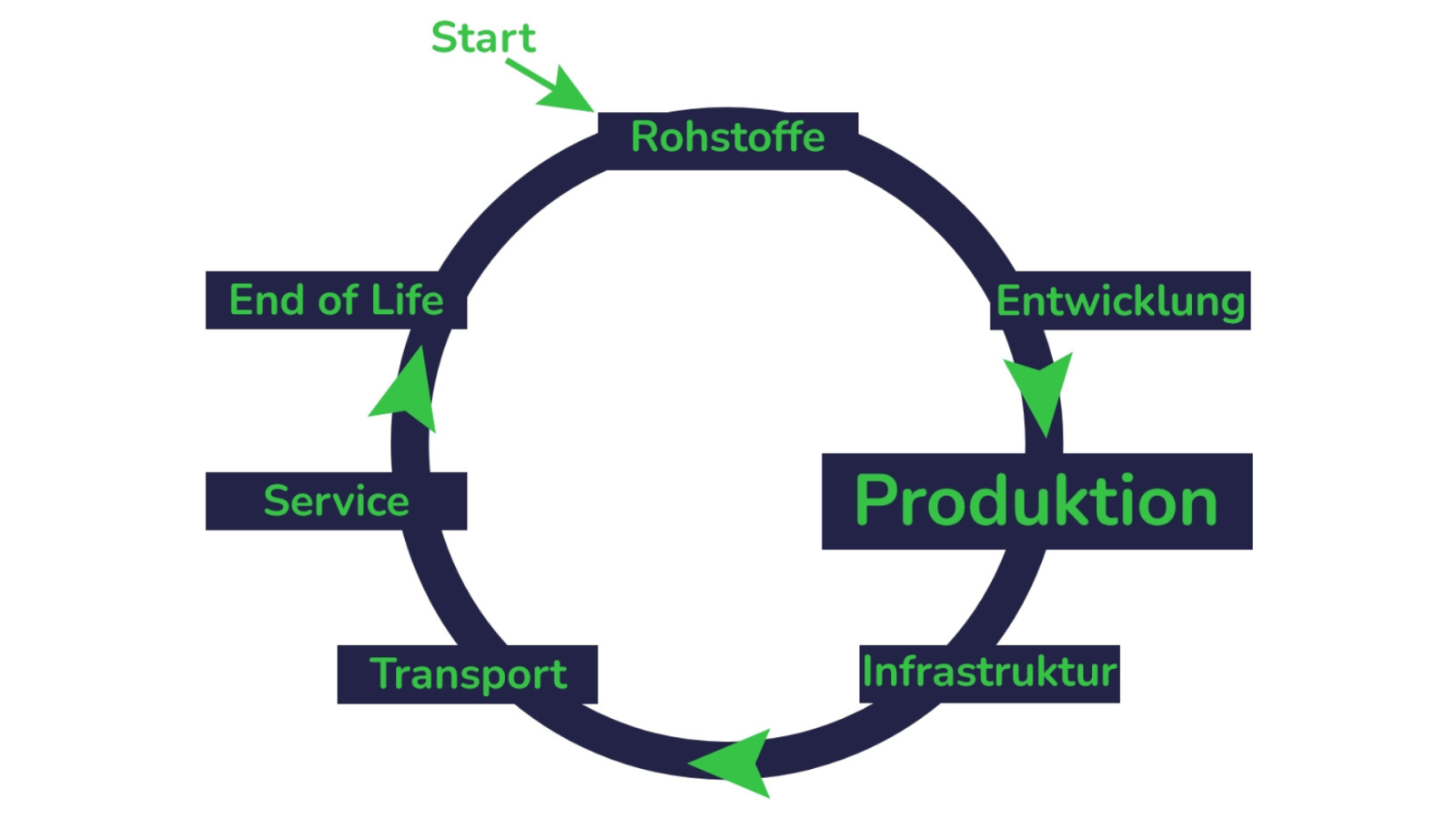

Resource savings along the value chain

The section of the value chain addressed includes raw material and production. The new AI-based solution optimises the structural calculations so that material is used more efficiently. Further benefits result from the automation of the planning process, which compensates for the shortage of skilled labour and increases efficiency in structural calculations without compromising on safety or quality. In addition, further savings can be realised in other trades if, for example, the substructure can be dimensioned smaller, thus saving materials there as well.

Resource efficiency through optimised static calculations

The use of AI significantly improves resource efficiency at Kalzip. Optimised static calculations save up to 3% of the aluminium used, which corresponds to around 60 tonnes per year. This reduces CO2 emissions along the supply chain by around 810 tonnes per year. The AI-based solution requires very little computing power, as the calculations are performed in just a few seconds once they have been trained. Thanks to the use of existing GPUs (graphics cards), the investment costs are low. Furthermore, due to the material savings and efficiency gains, the investment is amortised within a short time - probably in less than a year. The long-term savings significantly exceed the initial costs, which leads to a sustainable and economic improvement in production processes. Optimised substructures can also have positive effects on other trades.

Presentation of the pilotproject with the Kalzip GmbH

- Lukas Stein, Heismann Drehtechnik GmbH

- Julian Wolter, Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI)

Technology

AI capability: Data analysis and optimisation

AI models: Large AI-based static structural analysis assistant optimises key production parameters

Value creation

Phase: Production

Aim of AI: Optimisation of static calculations

Resource efficiency

Savings of up to 3% of the aluminium used (60 tonnes per year) and therefore 810 tonnes of CO2 per year