Reduction of overproduction in PCB manufacturing through AI

Schaltungsdruck Storz GmbH + Co KG faces the challenge of minimising the resource-intensive, but required, overproduction of printed circuit boards (PCBs). The current approach to controlling overproduction often results in non-reusable PCBs. The targeted use of artificial intelligence (AI) to better predict bad parts aims to minimise the number of good parts unnecessarily overproduced as buffers, which not only lowers material and energy costs, but also reduces the environmental impact.

High-precision printed circuit boards from the Breisgau region

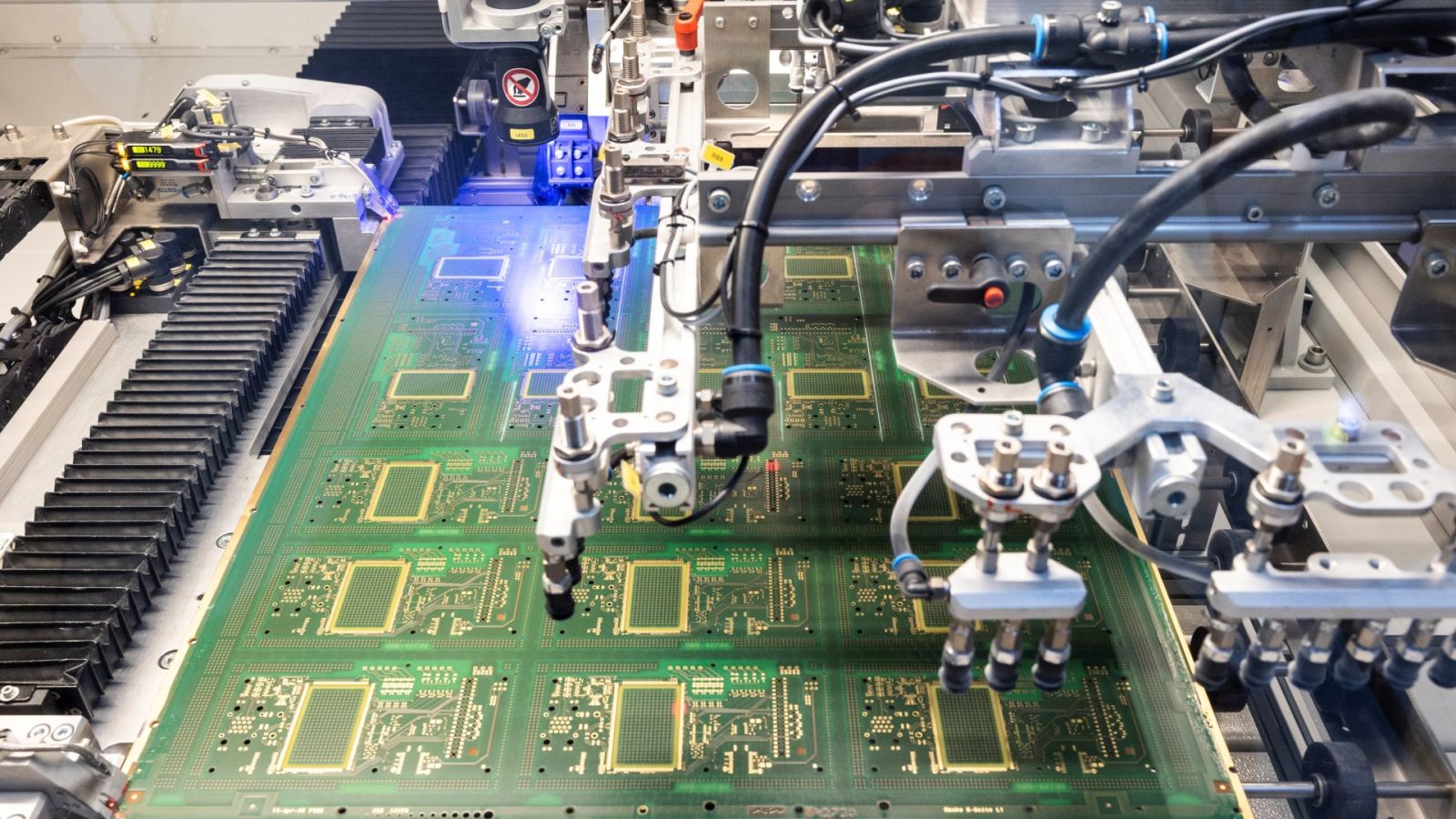

Schaltungsdruck Storz GmbH + Co KG from Kenzingen manufactures high-precision, printed circuit boards (PCBs) for various industries. Production includes numerous process steps such as chemical cleaning, pressing, drilling and milling, exposure, etching and galvanising processes. These steps place complex demands on materials and precision. Raw materials such as copper, gold, epoxy resin, glass fibre, polymer plastics and various chemicals are used for the individual steps.

Challenge: Reducing overproduction

The production of printed circuit boards is resource-intensive and, due to its complexity, is accompanied by unavoidable rejects in production(which requires overproduction to ensure the delivery quantity). This overproduction leads to increased material consumption and costs, as well as unnecessary environmental pollution. At present, the production quantity is determined on the basis of employees' experience, but this is not very precise. This leads to a surplus of good parts that are not utilised for various reasons and generally must be disposed of.

Precise predictions in production with the help of AI

An AI system should minimise the extent of overproduction by accurately predicting production requirements. To this end, the quantity of inherently occurring bad parts is predicted.. This depends largely on the degree of complexity and characteristic properties of the printed circuit boards produced. The AI system can be trained using the company's extensive database of past production processes, and as the data is partly unstructured, large language models (LLMs) are also used in the data preparation step.

In the new AI-supported process, an optimal estimate is made for the number of PCBs to be produced based on the PCB layout and the customer's delivery specifications. This minimises the overproduction of unusable good parts.

Resource savings through AI-based data analysis

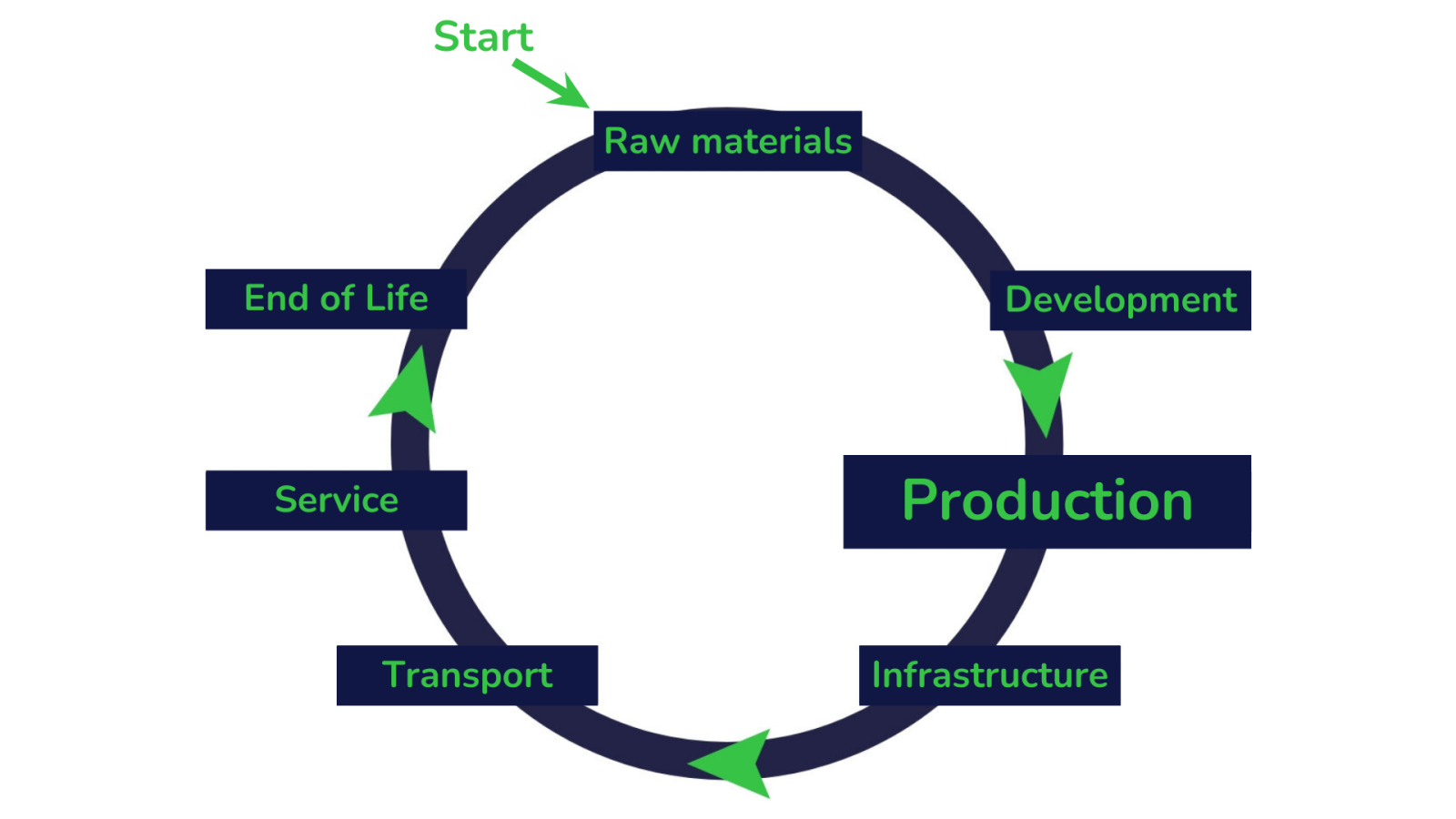

The addressed section of the value chain is production. The AI solution improves production processes by reducing overproduction and thus saving material and energy. This lowers costs and reduces waste, which strengthens the company's sustainability. In addition, more precise planning enables more efficient use of resources and increases competitiveness.

Saving resources through the use of artificial intelligence

The use of AI leads to a significant improvement in resource efficiency within the company. More precise predictions of production requirements reduce overproduction, which lowers both material consumption and energy requirements. As a result, the company saves around 3,370 kg of material per year, including 150 kg of copper, 170 kg of aluminium, 1,275 kg of epoxy resin, 1,775 kg of glass fibre and various chemical mixtures. The use of AI means that less energy is required, as the optimisation of production processes also leads to a reduction in CO2 emissions. Reducing the production volume also results in less contaminated wastewater that needs to be treated.

The necessary calculations of the AI system per order only require a few seconds of computing power and can be run on end customer hardware.

Presentation of the pilotproject with Schaltungsdruck Storz

- Philip Reuter, Schaltungsdruck Storz GmbH + Co. KG

- Marc Schubhan, Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI)

Technology

AI capability: Data analysis

AI models: Large Language Models (LLMs), Random Forests

Value creation

Phase: Production

Aim of AI: Forecasting production requirements

Resource efficiency

Reduction of overproduction through more precise forecasts of production requirements

Material savings of around 3,370 kg per year

Company

Industry: Production and distribution of printed circuit boards (PCBs)