AI-supported object recognition for returning products to the material cycle

System 180 plans, produces and sells modular, fully dismountable furniture system of the same name. In line with the current corporate strategy, a circular economy business model is to be established. Through the development of the Digital Product Passport (DPP) and the application of artificial intelligence (AI), the AI pilot project with the Green-AI Hub Mittelstand is increasing resource efficiency in both the manufacturing and utilisation phases. The solution can significantly reduce the resources required for various production processes and keep furniture and components in the material cycle.

Modular furniture systems from Berlin

System 180 from Berlin produces modular furniture systems that customers can configure according to their own ideas. Production includes the processing of stainless steel profiles into structural components and arranging medium density fibre (MDF) plates into infill panels using wood and metal processing manufacturing methods. The steel components can be powder-coated if required. System 180 uses metals such as iron, copper, aluminium and organic materials such as MDF. The furniture is assembled by service partners on site at the customer's premises.

Challenge: Optimisation of inventory management

In order to establish a circular business model, a return system must be developed for furniture and parts that are held by customers, logistics partners or in the company's own warehouses. The wide variety of modular designs makes recording complex and mobility-intensive; error-free communication between the parties is also time-consuming. The AI pilot project aims to solve these challenges using computer vision technologies and a digital product passport in which all furniture and its status are recognised and catalogued, facilitating inventory management. .

State and quantity detection with the help of AI

The web application includes object recognition as well as automatic storage and updating of the DPPs of the individual furniture parts. AI object recognition efficiently records and catalogues selected furniture as well as the number and condition of the respective components. The results of the object recognition are then documented in a DPP together with information from product-related databases. The catalogued furniture and components are stored in a ‘collection’ (as a metaphorical warehouse), which significantly increases reusability. This web-based solution can be used internally in production and sales as well as externally by customers.

The conditions at System 180 are ideal, as numerous real and synthetic image data are already available for model development and will be made available in the future to optimise the model. The modular solution can be extended to the entire product portfolio and promotes the transition to a circular economy - which significantly reduces the consumption of resources and raw materials.

Process optimisation along the value chain

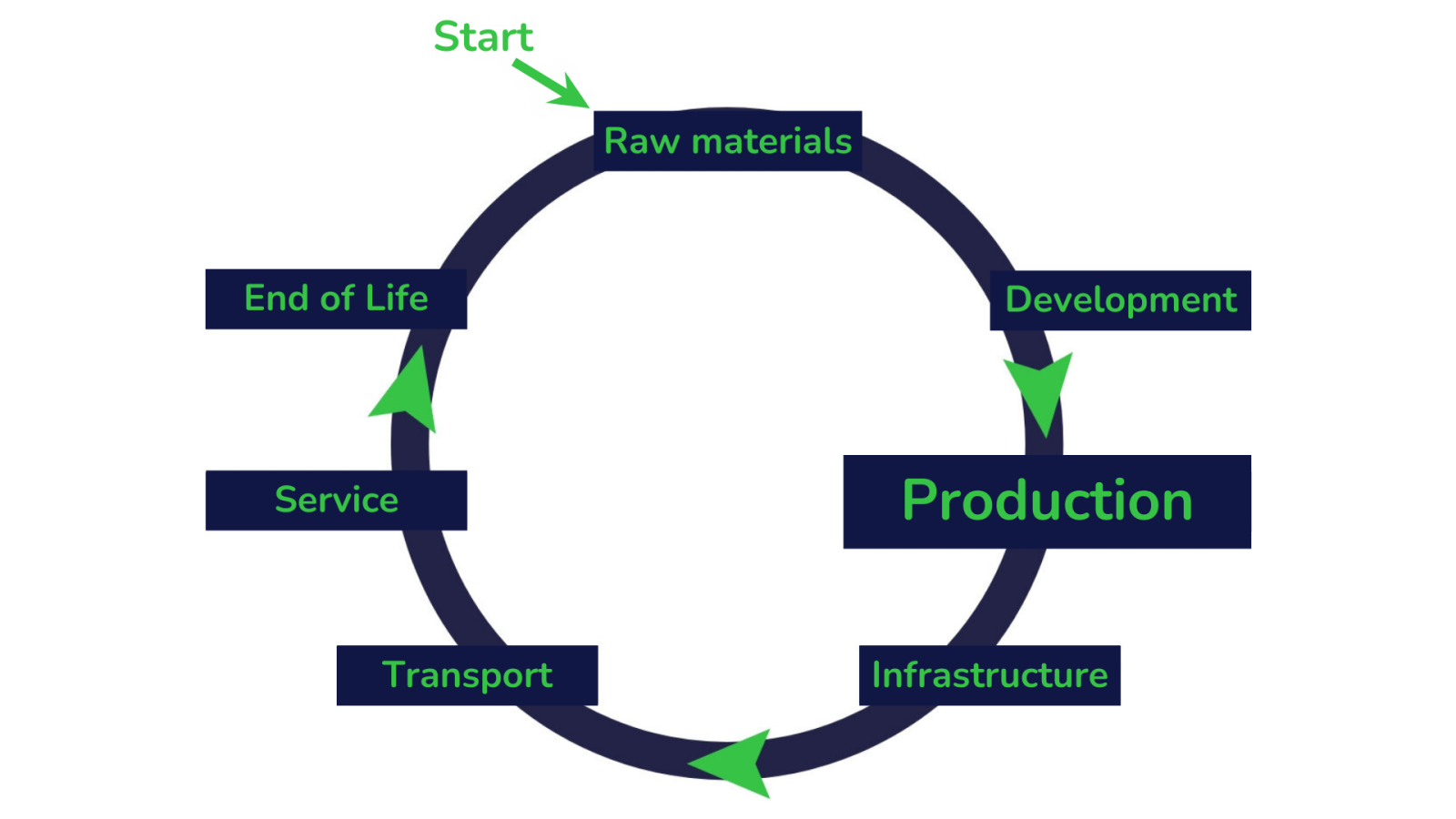

The planned solution optimises several phases of the value chain:

- Production/powder coating: Components are efficiently recorded and picked before and after powder coating, which was previously done manually using templates.

- Service/assembly: Here, components are precisely assembled into furniture using parts lists and assembly instructions.

- Service/conversions/repairs/returns: As part of these process stages, the stock and condition of the components is automatically recorded and synchronised with the Enterprise Resource Planning system using DPP.

- Raw materials/production: By recovering components that have already been used and storing them in ‘collections’, components can be reused and do not have to be manufactured again, which can save up to 20 per cent on raw materials.

- Development: Stored conditions help to improve product quality and design more sustainably in the long term.

In summary, the web application will save an enormous amount of time and resources. Customers will also benefit from easier parts replacement, expansion options for their furniture system and a lower error rate.

Conserving resources through digital inventory and component recognition

The use of AI increases resource efficiency by recording furniture and loose stock in a resource-saving manner or identifying faulty components at an early stage. This saves material and reduces CO₂ emissions. Internal production processes can be optimised in terms of both time and personnel. AI also enables the return process that needs to be established to close the material cycle. In addition, the previously time-consuming and error-prone communication effort regarding stocks located in geographically different places is no longer necessary. In the future, specialised staff will no longer have to travel to take stock as the data will be recorded digitally.

The main costs of the AI system lie in the initial development and training as well as the ongoing server costs for operating the system. The savings result from reduced material and transport costs, meaning that the investment can be amortised quickly depending on the production volume and error rate.

Presentation of the pilotproject with the System 180 GmbH

- Francesco Coccia, System 180 GmbH

- Jonas Brozeit, Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI)

Technology

AI capability: Object recognition (incl. counting) and condition assessment with storage in the digital product passport

AI models: Computer Vision

Value creation

Phase: Production, assembly, distribution, utilisation phase, warehouse

Aim of AI: Resource-saving return of furniture to the product cycle through efficient identification and tracking; simplification and optimisation of concentration-intensive routine tasks (e.g. in warehouse management, production or sales)

Resource efficiency

Reduction of resources through traceability of stocks, reuse and detection of faulty components