AI-based recommendation system for power electronics construction

Pikatron GmbH from Usingen manufactures customised, small batch power electronics. Many of the company's orders have specific electrical and mechanical requirements, making it difficult to ensure consistent product quality and to document the manufacturing process and construction specifications. The AI pilot project aims to develop an AI recommendation service based on the existing data collection. This is intended to help developers make better use of Pikatron's historical knowledge in order to save development time and minimise waste.

Power electronics from Usingen

Power electronic development requires materials such as metals (e.g., iron, copper and aluminium), fossil-based materials (e.g., potting compounds, coil formers and insulating films), organic materials (packaging) and core materials (ferrites). The electronic products are developed on the basis of customers' technical requirements and their needs. This also includes the development of prototypes. After successful testing, these are then released for production and continuously checked with further tests.

Challenge: Making historical development knowledge usable in a context-sensitive way

At present, technical enquiries with very specific electrical or mechanical requirements are forwarded to individual developers who then develop the products based on their experience. This process uses knowledge and data from previous developments, however, this data is difficult to access and search. The challenge is, therefore, to make historical knowledge available to other developers in a context-sensitive way. For example, if iterations of prototypes could be saved, then developers would be able to start later in the iteration cycle and simply just adapt the existing prototypes.

More efficient product development with the help of AI

The project aims to develop a recommendation system based on existing data collection. This system should enable developers to quickly and efficiently access existing knowledge and documentation in order to create consistent and optimised product specifications. This can significantly reduce the reject rate and material waste for example, during prototype development.

First, the technical requirements of the product developers are formalised so that they can be processed by the recommendation system. Knowledge graphs will be used to store and link data from developed concepts, prototypes and products. The knowledge graphs are to be developed with the involvement of specialist users, and structural knowledge models (domain ontologies ) will be created for the respective subject area.

Furthermore, KPIs (key performance indicators) are defined, for example, for material efficiency and scrap reduction, which the system should consider when generating proposals. On this basis and through machine learning approaches such as link prediction and case-based reasoning, a corporate memory is created that breaks down data silos, enriches data and enables a comprehensive search.

Saving resources through targeted data suggestions

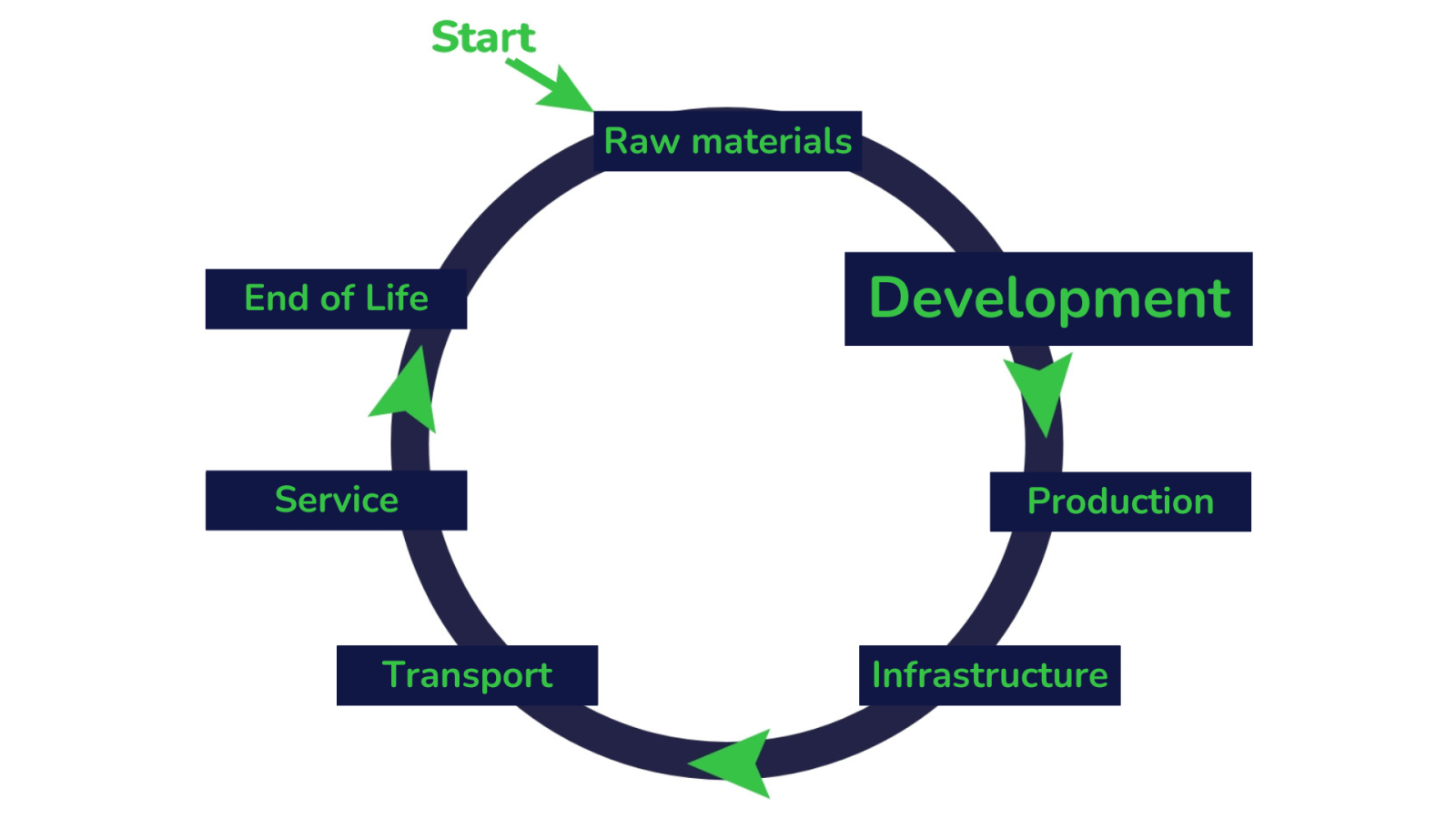

The project addresses the section between development and production in the value chain. The historical data is difficult to search and access due to the specificity of the electronic components and the involvement of multiple parties. The recommendation system with the developers' data is intended to provide them with suitable, novel suggestions. The availability of test results, prototype validations and series productions support developers in the development of new customised electronics through context-sensitive knowledge. Instead of having to gather the same (or similar) experience again by using materials and personnel, developers can build on the proposed construction plans and measurement results of historical prototypes. This shortens the development process and reduces the number of cycles required for development. In addition to saving materials, another advantage is that shorter development time means customers can be offered a suitable product sooner.

Resource efficiency via an intelligent recommendation system

The aim of the pilot project with the Green-AI Hub Mittelstand is to make historical knowledge more accessible and readily available. The recommendation system developed for this purpose is intended to suggest suitable historical electronic components to developers. The combination of measurement and storage data should enable material to be used more resource-efficiently. One KPI for measuring resource efficiency is the savings in prototype development. The costs of AI will mainly relate to the development of the approaches themselves, however, these are also estimated to be lowas the approaches do not involve large models. In the productive environment, the costs of the AI will mainly be attributable to the energy costs of the server on which the recommendation system runs.

Presentation of the pilotproject with the Pikatron GmbH

- Dr. Florian Klug, Pikatron GmbH

- Michael Schulze, Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI)

Technology

AI capability: analysing, assisting

AI models: Knowledge graph-based recommendation system optimises the use of materials in customer-specific power electronics

Value creation

Phase: Development

Aim of AI: Optimisation of the use of materials in the development of construction plans

Resource efficiency

The intention is to save iron, copper, aluminium, potting compounds, coilformers and insulation foils.