AI-based optimisation of turned parts production

HEISMANN Drehtechnik is a manufacturer of precision turned parts whose main challenge is to design automated production processes in such a way that process stability is guaranteed during regular operation. Production interruptions and disruptions caused by material fluctuations, for example, require extensive readjustments by employees and lead to rejects. The aim of the joint AI pilot project is to reduce waste and save human resources through early error detection and optimised readjustment.

Precision turned parts from the Niederbergisch region

HEISMANN Drehtechnik was founded in 1918 and today, with 135 employees, is an established manufacturer of precision turned parts. With state-of-the-art machinery including 27 CNC multi-spindle automatic lathe machines and seven CNC turning/milling centres, precision turned parts are manufactured from a variety of materials such as steel, brass, aluminium and copper.

Challenges: Reducing production disruptions in the manufacture of precision turned parts

Production interruptions and malfunctions mean that the process must be repeatedly readjusted. In this case, the production of rejects is far more likely and sometimes even unavoidable. In order to avoid such production disruptions and interruptions for as long as possible, employees must continuously monitor and adjust the process. Manual tool correction is a key control variable here. The necessary adjustments depend on numerous influencing factors, however, many of these factors are not transparent to employees and their impact on the stability of the process is difficult to predict.

Early detection of errors and optimised readjustment through artificial intelligence

The aim of the AI pilot project is to reduce the reject rate with the help of early detection and optimised readjustment. Due to the large number of influencing factors (material, temperature, tools, etc.) and the limited transparency, manual readjustment by employees is reaching its limits. This is where AI’s ability to analyse large volumes of data can be put to profitable use. The reduction in process-related waste due to the AI pilot project is leading to a significant increase in resource efficiency. Artificial Intelligence makes it possible to process more information at an early stage and to make the findings available to all employees in the form of recommendations for action. This enables employees to react more quickly and effectively to changes and disruptions in the process. Machine learning (ML) algorithms and small neural networks are used to predict the probability of errors and generate recommendations for action for the axis settings of the machines and the prediction of tool life.

Saving resources through AI-based process optimisation

The use of an AI solution simplifies the work of employees who previously often had to rely on their experience and judgement to control the production process. With the help of AI, they can make more informed decisions that make the manufacturing process safer. This makes the company more competitive, as there are fewer quality defects and complaints, which are particularly unacceptable with high-precision turned parts. The AI solution also helps to reduce the workload in quality assurance, as early warnings can be given when there is a high probability of defective parts being produced. The use of AI takes data acquisition on the machines and the measurement of parts to a new level, further supporting the digital transformation of HEISMANN Drehtechnik.

Saving resources using artificial intelligence

The optimised process control reduces waste, which primarily saves on raw materials such as steel, aluminium and brass. This saving is expected to amount to around 10,700 kg per year. In addition, other resources such as electricity (approx. 19,600 kWh per year), coolant, time and labour are saved, as they do not have to be used for the unnecessary production of faulty parts. This ultimately contributes to a significant reduction in CO2 emissions. In addition, the service life of the moulds is to be extended, leading to a reduction in machine downtimes and thus to further savings, as the restarting of machines increases the susceptibility to the production of rejects.

Presentation of the pilotproject with Heismann Drehtechnik GmbH

- Martin Gawenda, Heismann Drehtechnik GmbH

- Johannes Solzbacher, Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI)

Technology

AI capability: analysing data, making recommendations for action

AI models: regression models, random forests, LSTMs, GRUs

Value creation

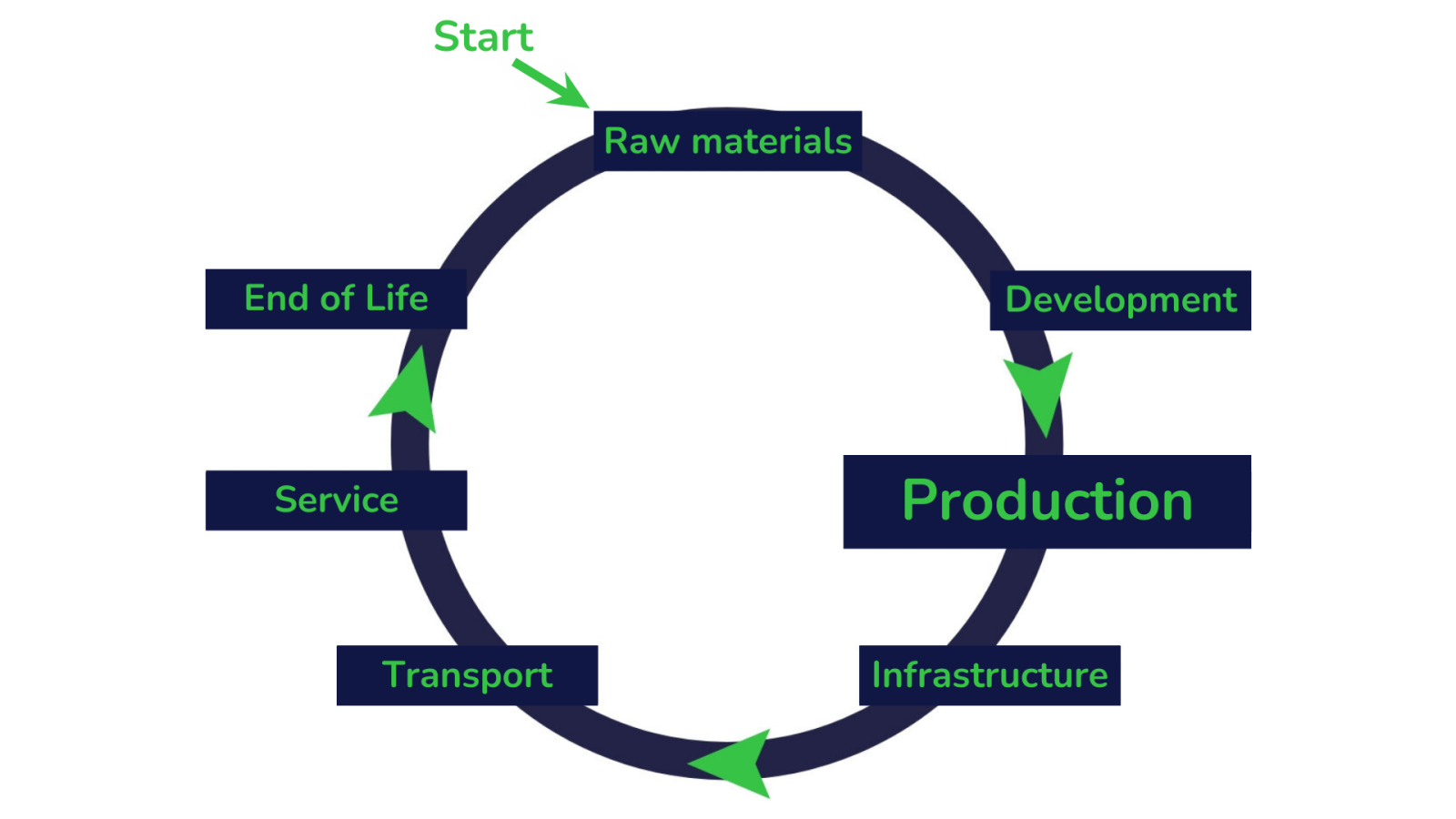

Phase: Production & quality control

Aim of AI: Detection of errors to avoid rejects, optimisation of downtimes

Resource efficiency

Reduction of the error rate by 20% and resulting material savings