AI-based process data analysis in precision tube manufacturing

MPG Mendener Präzisionsrohr GmbH is a manufacturer of thermotechnical products from Menden, North Rhine-Westphalia. The AI pilot project with the Green-AI Hub Mittelstand aims to use an AI solution to automate and improve the production parameters in the production process by reducing waste and maintaining the high quality of the products.

Innovative heat exchanger tubes from the Sauerland region

MPG Mendener Präzisionsrohr GmbH manufactures innovative heat exchanger tubes and thermotechnical products. The casting process , the first production step, plays a key role here. Today, the parameters depend heavily on the experience of the employees, which can lead to fluctuations in quality. MPG's aim is to make the production process less dependent on the experience of employees through automated parameter optimisation, and to make the casting process stable and resource-efficient in the long term.

Challenges: Reducing quality fluctuations and rejects during the casting processes

The casting process at MPG is heavily dependent on the experience of employees - a circumstance that can lead to quality fluctuations and rejects. With the impending age-related departure of experienced employees, valuable knowledge will be lost, and the casting processes could become less reliable. A key challenge is to optimise the parameters in such a way that consistently high quality is guaranteed even without individual expertise. As quality defects in casting are often only recognisable after the fact, it is important to reduce the reject rate as early and sustainably as possible.

Optimisation of the casting process with the help of AI

The AI pilot project will use AI-supported parameter optimisation to determine the optimum settings for the casting process. Machine data is processed for this purpose and fed into an AI-based analysis, which is examined to determine the best combination of factors such as temperature and time. The project relies on statistical test planning to understand the influence of parameters on rejects and quality. Through machine learning, employees receive recommendations for optimal settings or machine parameters are automatically adjusted. This reduces the dependency on experience and valuable knowledge gained by employees is recorded in a database. Optimisation begins in the casting process and can later be extended to other stages, such as pressing and pickling. The aim is to reduce waste and energy costs in the long term and ensure quality - an approach that strengthens MPG in times of skilled labour shortages and increasing quality requirements.

Resource savings during production

Thanks to AI-supported parameter optimisation, MPG gains efficiency and reliability in the casting process. AI algorithms calculate optimal settings that reduce rejects and increase production quality. This allows the company to save material and utilise energy in a targeted manner, reducing production costs. The automated settings relieve the burden on employees and compensate for the loss of knowledge due to age-related departures. With this data-based approach, MPG is creating a basis for scalable automation and therefore more stable, more cost-effective production. Subsequent production steps, which are better coordinated thanks to AI-optimised parameters, also benefit in the long term. This makes MPG more competitive thanks to reliable, resource-efficient processes, enabling the company to better achieve sustainability goals.

Increasing resource efficiency through AI-supported production optimisation

AI-supported optimisation helps MPG to conserve resources in the casting process in a targeted manner. Optimised furnace temperatures not only reduce waste, but also material and costs. MPG has wanted to reduce CO₂ emissions and make production more sustainable for years. AI-supported optimisation in the casting process brings MPG even closer to its goal of climate neutrality by 2030. Automation also improves working conditions: Employees spend less time in the energy-intensive casting shop, which is not only more comfortable but also saves working time. In the long term, the optimisation can be transferred to other steps such as pressing and pickling so that MPG can continue increasing resource efficiency throughout the entire production process.

Presentation of the pilotproject with the MPG Mendener Präzisionsrohr GmbH

- Dr. Andreas Gahl, MPG Mendener Präzisionsrohr GmbH

- Sven Pultar, Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI)

Technology

AI capability: Data analysis

AI models: machine learning

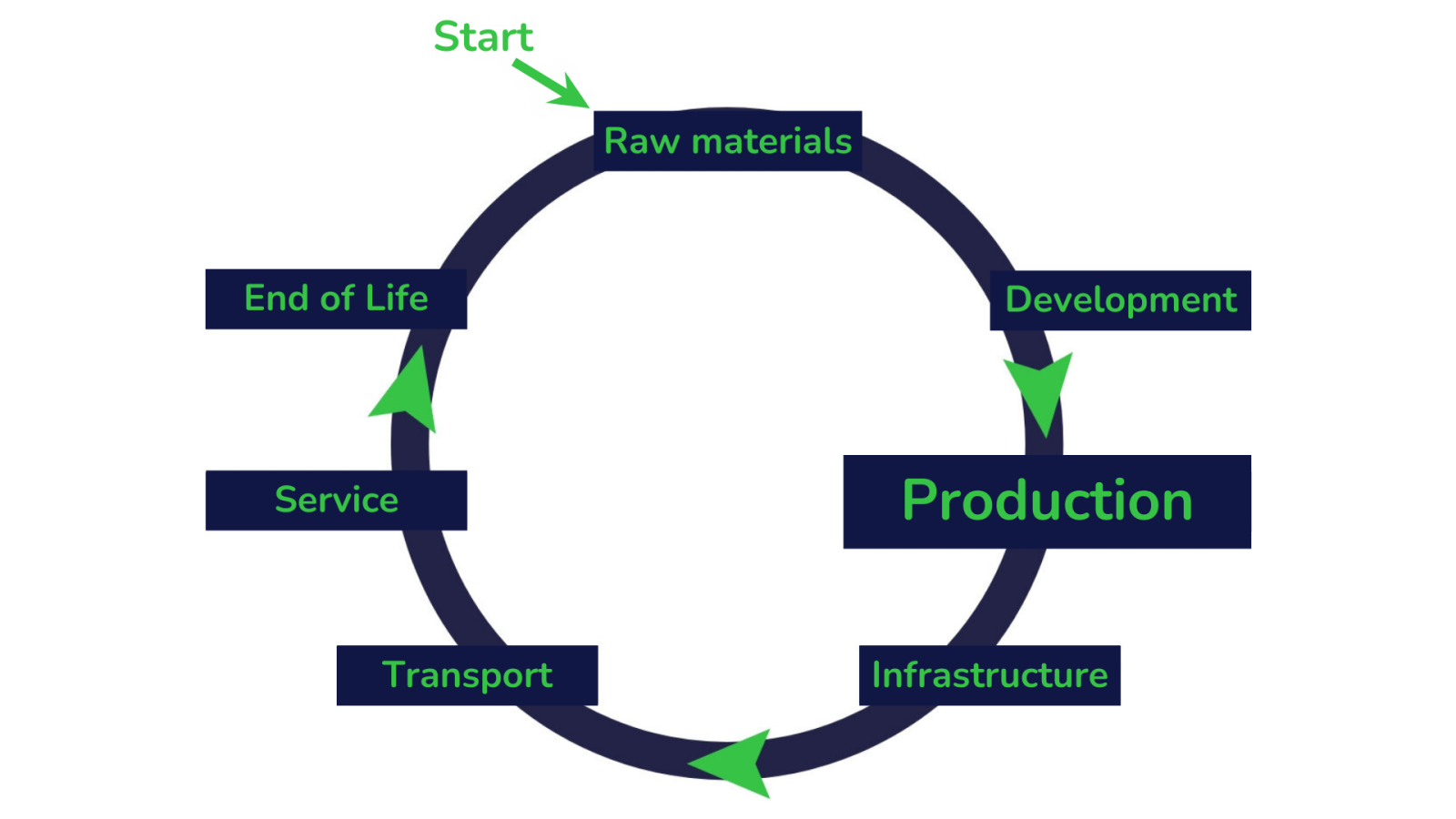

Value creation

Phase: Production

Aim of AI: Predicting the production parameters

Resource efficiency

Reduction of overproduction and quality assurance through more precise prediction of production parameters