AI-based optimisation of supply chains

ULT AG from Saxony aims to plan material requirements and order times more precisely to avoid excess stock and high storage costs. The AI pilot project with the BMUV's Green-AI Hub Mittelstand intends to improve material procurement and warehousing though the use of AI. This should enable precise demand forecasts in order to optimise the scope and timing of orders. This not only reduces storage costs and capital commitment but also minimises the risk of having to dispose of specific materials when certain products run out. Thanks to more efficient transport logistics and resource utilisation, material and energy consumption (and the resulting CO2 emissions) can be significantly reduced.

Air technology from Löbau

ULT AG produces extraction and filter devices for air purification as well as systems for process air dehumidification at its site in Löbau, Saxony. These systems are used in a wide range of industries, such as mechanical engineering, electronics manufacturing, medical technology, laboratories, trade and additive manufacturing. ULT uses high-quality materials and components made of steel, copper, aluminium and plastic. The ordering and warehouse processes are currently controlled using manual planning, which requires intensive data maintenance and administration.

Sustainable optimisation of ordering and warehouse processes

The AI pilot project of the Green-AI Hub Mittelstand is intended to enable ULT AG to plan material requirements and procurement processes more precisely to reduce excess stock, scrapping and storage requirements. Currently, requirements are determined using an Excel tool, which is time-consuming to maintain and requires extensive experience on the part of the planner. A more efficient solution would be to use an AI-supported system that creates data-driven demand forecasts, optimises procurement parameters and considers the individual circumstances of potential suppliers. This can sustainably reduce material waste, storage costs and CO2 emissions.

Intelligent tool for precise planning

The new applicationsfocus on time series analyses, uncertainty quantification and explainable AI (XAI) for the transparent and reliable prediction of material requirements and the configuration of procurement orders. The combination of machine learning methods with ‘human-in-the-loop’ functionalities allows predictions to be validated by experts and adjusted if necessary. Historical order, stock and consumption data form the basis for forecasts and are supplemented by external market information. Additional data sources can be integrated for specific analyses. With the planned approach, the AI system continuously analyses the data and generates recommendations that are reviewed and used by experts. This enables well-founded, comprehensible decisions to be made that reduce stock levels and excess stock, optimise logistics processes and reduce CO2 emissions - an important step towards sustainably increasing efficiency at ULT AG.

Data-driven decision-making strategies in logistics

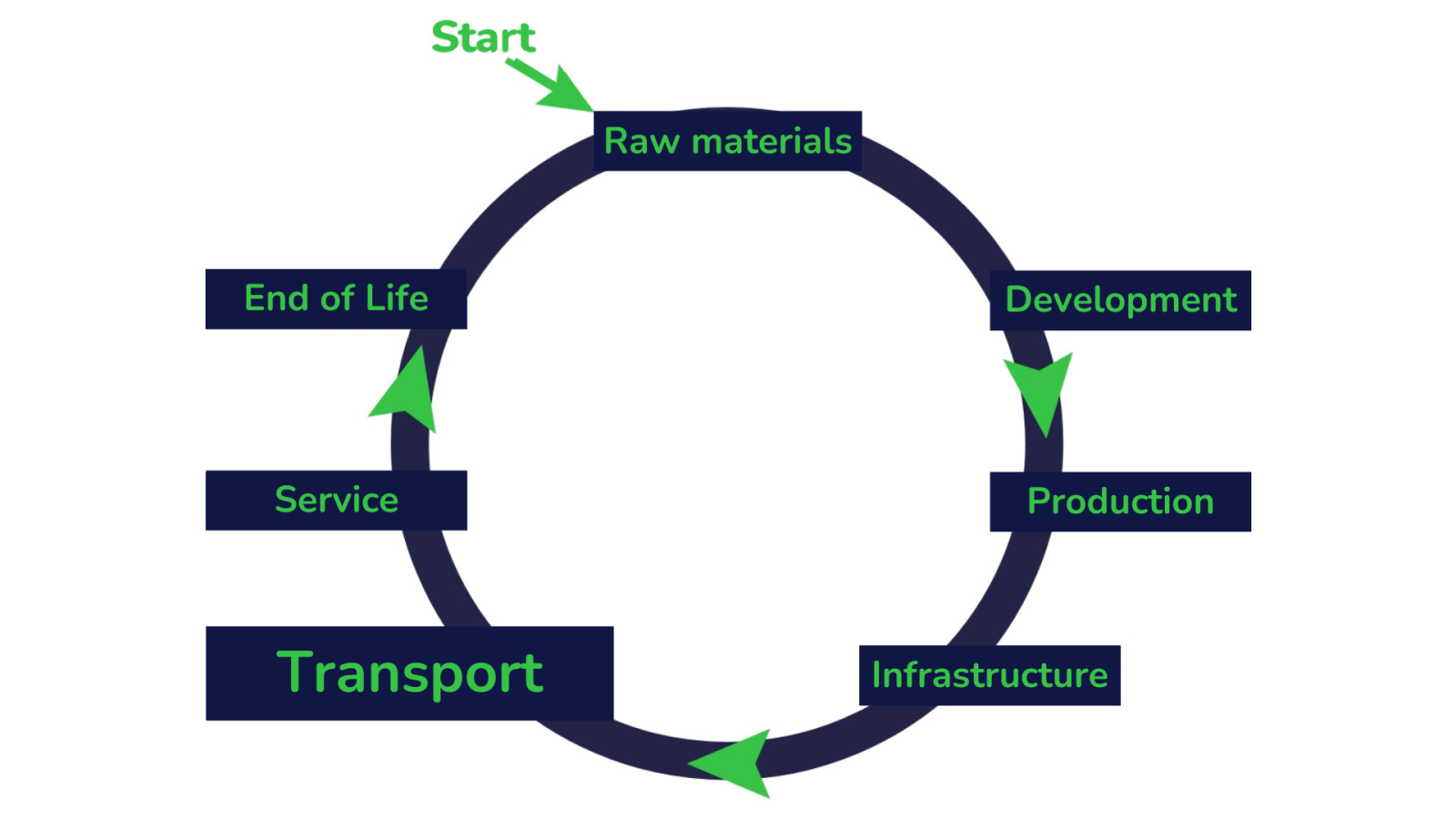

The project addresses critical areas of the value chain, in particular material requirements planning, procurement, warehousing and logistics. With the AI-supported solution, ULT can derive demand forecasts more accurately and flexibly from acute scenarios so that the timing, quantities and frequency of procurement processes are aligned with both economic and ecological goals. This reduces the amount of capital tied up and the risk of excess stock that must be scrapped at a later date. Targeted data analyses, an improved understanding of demand cycles and the consideration of documented experience with suppliers make order management faster and more precise. Even less experienced planners can be supported in the execution of procurement processes through the data-based approach. This can prevent errors and provide employees with additional decision-making certainty. The solution also helps to gain an overview of certain effects (such as incurred expenses due to logistics processes) and incorporate them into decisions. This avoids unnecessary journeys between warehouse and production sites, resulting in a positive impact on the company's carbon footprint. This data-driven strategy not only creates cost savings and increases efficiency but also supports ULT in its goal of operating more sustainably and further reducing its environmental impact.

Resource efficiency through optimised processes

The use of AI at ULT significantly improves resource efficiency, as more precise demand forecasts and optimised ordering processes reduce excess material stocks and storage costs. This could save around 5 tonnes of steel, 400 kg of copper, 200 kg of aluminium and 400 kg of plastic every year. Energy consumption is also reduced as storage space is used more efficiently, and transport costs are reduced thanks to optimised logistics processes. This leads to a significant reduction in CO2 emissions. The implementation costs of the AI solution are expected to be amortised within two years through savings in materials, storage and logistics. In the long term, this sustainable increase in efficiency will strengthen ULT's competitiveness and reduce the company's ecological footprint.

Presentation of the pilotproject with the ULT AG

- Nele Ganze, ULT AG

- Andreas Emrich, Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI)

Technology

AI capability: analysing, making recommendations

AI models: Time series analyses, uncertainty quantification and explainable AI (XAI)

Value creation

Phase: Material requirements planning, procurement, warehousing and logistics

Aim of AI: More precise demand forecasting and optimised ordering processes

Resource efficiency

Savings of around 5 tonnes of steel, 400 kg of copper, 200 kg of aluminium and 400 kg of plastic per year