AI-based predictive maintenance on cooling towers

Maintenance and servicing are important measures to ensure the functionality and longevity of a product. But when is the best time to carry it out? Different usage behaviour and environmental influences lead to different stress profiles and wear curves. Accordingly, it is difficult to carry out maintenance at the right time. Manufacturing companies usually specify a fixed interval for necessary maintenance work. The actual condition of the product is not taken into account.

Company presentation incl. initial situation

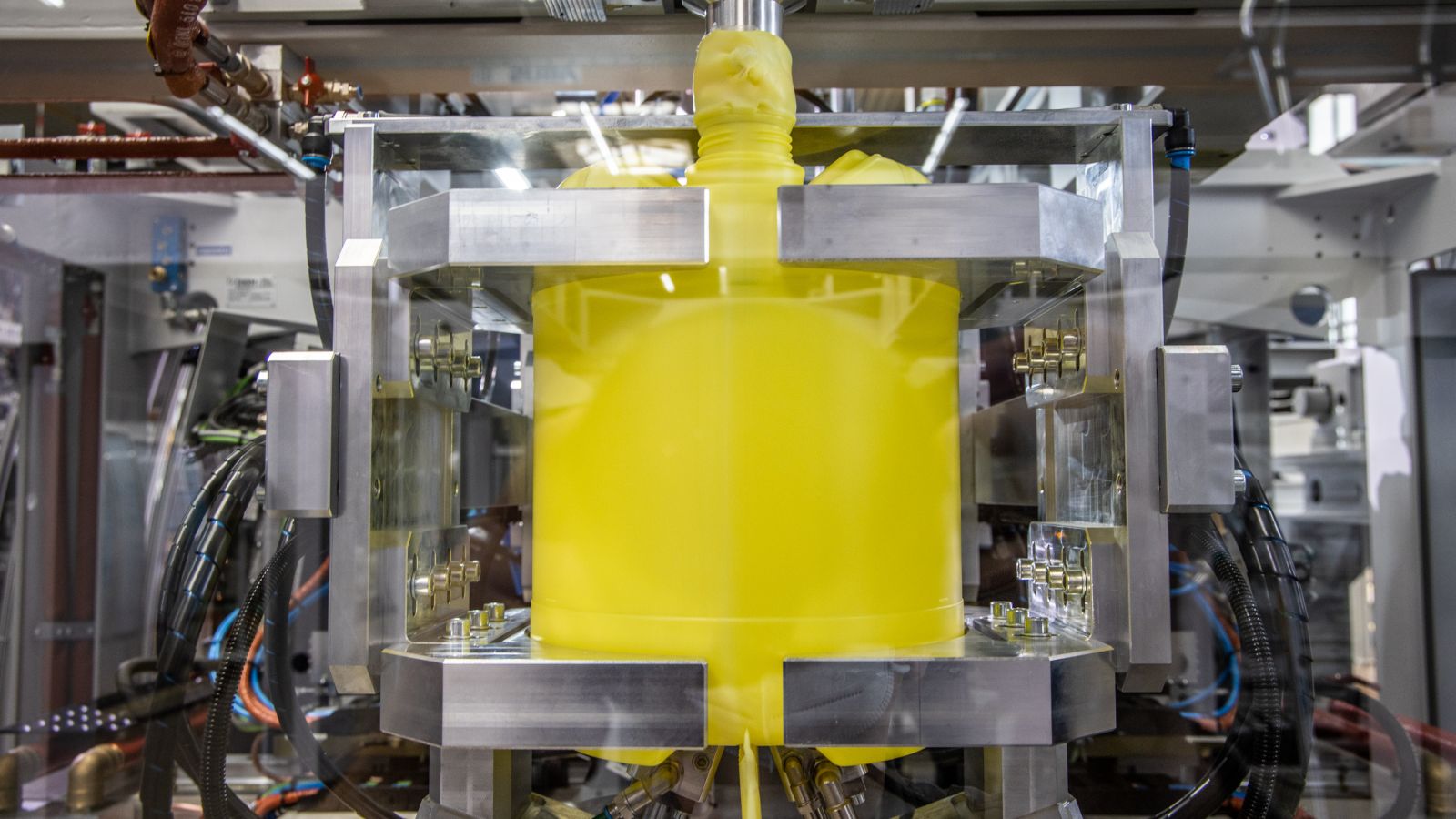

MULTI Kühlsysteme GmbH has been offering complete systems in the field of industrial cooling systems for over 25 years. This includes inventory, planning, technical processing, production, assembly, control, commissioning and service. The systems are used in the glass, metal, chemical and solar industries, among others.

The challenge

The functionality of cooling systems often has a critical impact on customers' processes. In the event of malfunctions, fast and reliable rectification is important for high customer satisfaction. With customers in over 60 countries, this situation is a major challenge for the SME due to scarce human resources. The company had already installed remote maintenance modules in the plants, which are used for condition monitoring and enable analysis of past failures. However, predicting maintenance cases was not possible until now.

Artificial intelligence as the solution

To enable predictive maintenance, an AI system was developed that is able to predict and, at best, avoid failures. This can be detected on the basis of creeping value shifts in the data of the remote maintenance modules and thus uncovered at an early stage. For this purpose, a machine-learning model was trained with the help of time series analyses of the cooling systems and linked to the experience knowledge of the specialist staff. During operation, the normal curves are then compared with the sensor data from the remote maintenance modules of the cooling towers, allowing the maintenance status of the cooling towers to be monitored.

Value creation

With predictive maintenance, the cooling towers can be individually monitored and serviced as needed. On the one hand, this means that specialist personnel can be deployed much more efficiently and, on the other hand, the failure rate of the systems can be reduced through early detection of possible damage. In addition, compared to fixed maintenance intervals, the service life of individual components can be significantly increased through predictive maintenance. These advantages improve plannability, reduce costs and working hours, which can also have a positive effect on customer satisfaction.

Plattform Lernende Systeme – Die Plattform für Künstliche Intelligenz (2021): KI im Mittelstand – Potenziale erkennen, Voraussetzungen schaffen, Transformation meistern, Bericht, Plattform Lernende Systeme – Die Plattform für Künstliche Intelligenz, München.

MULTI Kühlsysteme GmbH

...is a manufacturer and service provider of industrial process cooling systems. Together with the partner Fraunhofer IWU, a system was developed as part of the implementation project of the Mittelstand-4.0-Kompetenzzentrum Chemnitz, which detects deviations from the normal state based on the operating data and predicts failures. This way, the optimal time for maintenance can be determined much more precisely.

Technology

AI capability: act, understand

AI model: neural network, time series analysis

Value creation

Phase: production

Aim of AI: cooling tower maintenance

Resource efficiency

Reduction of cooling tower downtime

Efficiently controlled deployment of skilled personnel

Longer service life of components